3D printing has established itself as a revolutionary technology in several areas, especially in the medical device sector. With the ability to create high-quality and precision implants, this technology not only transforms the manufacturing of medical products, but also redefines training and surgical planning. CPMH stands out as a leader and innovator in this field, driving the use of 3D printing to offer personalized and effective solutions.

Precision and Customization in 3D Printing

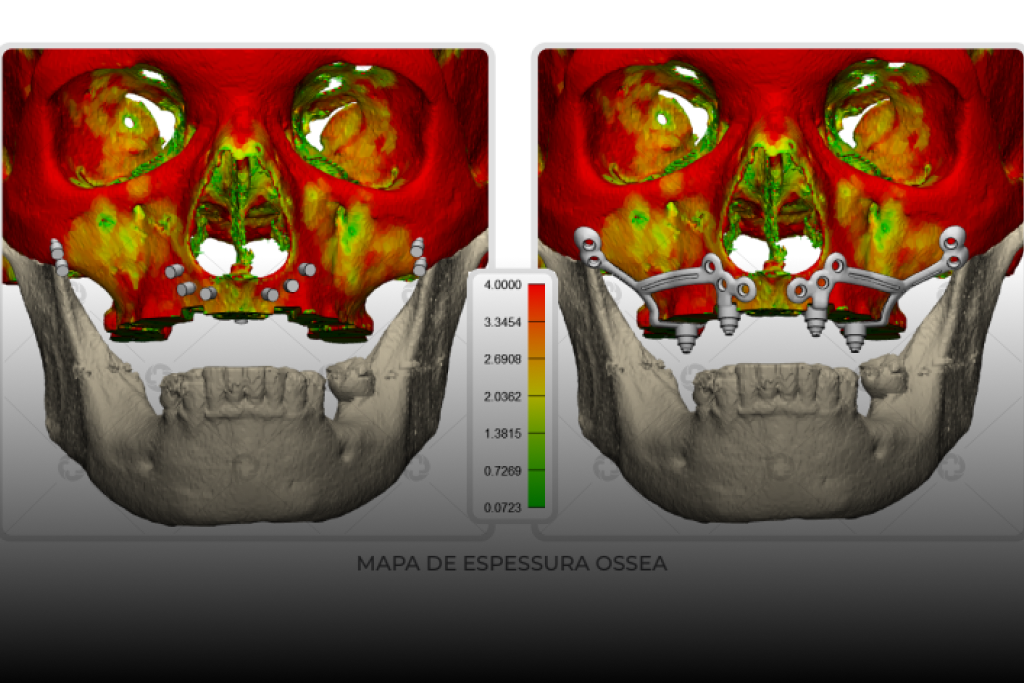

The ability to accurately reproduce each patient’s anatomical structures is one of the greatest innovations brought about by 3D printing. Using data obtained from CT scans, CPMH is able to create digital models that faithfully represent the individual’s anatomy. These models are then used to manufacture custom implants that fit perfectly to the patient’s body.

This precision is crucial in many areas of medicine, such as orthopedics, dentistry and reconstructive surgery. Customized implants not only improve the effectiveness of procedures, but also reduce the risk of complications, increasing patient safety.

Preoperative Training and Planning

In addition to implant manufacturing, 3D printing stands out as a valuable tool for preoperative training and planning. CPMH uses 3D printed anatomical models to allow surgeons to study a patient’s anatomy prior to surgery. These models provide a unique opportunity for physicians to perform procedural simulations, experiment with different surgical approaches and familiarize themselves with the unique challenges of each case.

This type of preparation not only increases surgeons’ confidence, but also contributes to reducing surgical time and postoperative complications. CPMH, by providing these innovative resources, is at the forefront of improving surgical practices.

CPMH Quality and Innovation

The quality of the implants produced by CPMH is ensured by the use of biocompatible materials and the application of the most advanced printing technologies: additive manufacturing by powder bed fusion, following criteria supported by national and international technical standards, allows the creation of complex and lightweight structures, which are ideal for application in medical devices.

CPMH not only keeps up with industry trends, but also leads the way in innovation. By investing in research and development, the company constantly seeks to improve its 3D printing techniques, ensuring that its products meet the highest standards of quality and effectiveness.

The Future of 3D Printing in Medicine

The future of 3D printing in medical devices is promising. Research into bioprinting is advancing, with the possibility of printing tissues and organs, which could revolutionize regenerative medicine. The integration of artificial intelligence and machine learning also promises to further optimize the design and production of implants, making them even more personalized and efficient.

Conclusion

High-quality, precision 3D printing is redefining the medical device landscape, especially in the production of customized implants. CPMH, with its leadership and innovation, stands out in this field, offering solutions that not only improve the quality of medical care, but also promote the safety and effectiveness of surgical procedures. As we continue to explore the possibilities of 3D printing, CPMH positions itself as a driving force for the future of medicine, delivering significant advances that will benefit patients and healthcare professionals alike.